Precision and Predictability: How Real-Time Visibility Boosts Your On-Time Delivery

In today's market, hitting your delivery window isn't optional. It’s expected. On-time delivery has become more than a logistics metric; it’s a business imperative that shapes how customers see your brand. When you deliver as promised, you build confidence. When you don’t, you pay for it in trust, revenue, and reputation.

But here’s the real differentiator: visibility. Companies that invest in real-time visibility tools don’t just ship on time more often. They move with more precision, make decisions faster, and operate with fewer surprises. This isn’t about luck or brute force. It’s about clarity across every link in your supply chain.

Let’s break down how smart tracking tech and integrated logistics workflows make all of this possible.

Advanced Tracking Technology: Your Window Into Real-Time Supply Chain

Real-time tracking gives you eyes on the entire journey — from warehouse to doorstep. With solutions like GPS, telematics, and Transportation Management Systems (TMS), logistics teams gain the kind of insight that turns reactive chaos into proactive control.

GPS Tracking: Enhancing Accuracy and Responsiveness

GPS tracking tells you exactly where a shipment is and when it’s expected to arrive. But more importantly, it gives you the lead time to fix problems before customers feel them. See a delay forming? You can reroute, reassign, or update the customer in real time. That kind of responsiveness turns breakdowns into moments of trust.

Imagine knowing a critical shipment is stuck 40 miles away due to a traffic snarl. With GPS in place, you don’t wait to find out. You act. That difference matters.

Telematics: Proactive Management of Fleet Operations

Telematics gives you more than just a location pin. It’s a full health report on your fleet — fuel usage, engine diagnostics, driver behavior. When you can predict issues like vehicle maintenance before they cause downtime, you protect delivery windows and reduce costly surprises. It’s less firefighting, more forecasting.

Companies using telematics often find secondary gains too, smoother driving lowers fuel costs, fewer breakdowns increase customer satisfaction, and insights help train better-performing teams.

Transportation Management Systems (TMS): Dynamic Optimization of Delivery Routes

A TMS connects the dots between your plans and the real world. It updates routes automatically based on traffic, road conditions, and weather patterns. That flexibility means fewer delays and better ETA accuracy. Your shipments take the smartest path, not just the shortest.

If your driver hits unexpected construction or a weather delay, your system recalibrates. The new route isn’t just efficient — it’s a lifeline for your delivery promise.

Integrated Logistics Solutions: Creating Predictable Outcomes

On-time delivery isn’t just about trucks and maps. It’s about how every part of your supply chain works together. When your logistics systems are integrated — warehousing, transportation, inventory — things move cleaner, faster, and with less friction.

Warehousing and Transportation Synergy

Inventory doesn’t do you any favors sitting on a shelf. When your warehousing and transportation systems talk to each other, you cut down on order processing time and shipping delays. Orders are picked and packed in sync with truck schedules, so nothing sits idle.

For example, a warehouse tied into the TMS can begin prepping outbound shipments the moment an order clears — no waiting, no confusion.

Enhanced Inventory Visibility

You can’t ship what you don’t know you have. Real-time inventory tracking gives you the confidence to promise availability and the data to manage demand. That means fewer stockouts, smarter purchasing, and more accurate fulfillment — all of which support your on-time delivery targets.

The best systems also flag when inventory isn’t just low, but moving abnormally. If one SKU’s velocity spikes, your team can act before the backlog grows.

Scalable Solutions for Market Fluctuations

Markets change fast. Demand can spike in a week or fall off in a day. Integrated logistics platforms help you adapt without breaking your delivery rhythm. Ramp up operations during peak times or dial them back during slow periods without losing efficiency or control.

That scalability protects margins too. You're not overcommitting during quiet seasons or missing out when the market heats up.

Industry-Leading Results: Achieving Exceptional On-Time Delivery Rates

Companies that run their logistics with this level of visibility and integration are outperforming the field. We’re talking on-time delivery rates above 98 percent — a number that doesn’t just meet industry standards but leaves them behind.

Automotive Logistics: Ensuring Production Continuity

In automotive, every delivery is part of a tightly choreographed dance. One late part can stall an entire production line. Real-time logistics management keeps everything on schedule so just-in-time (JIT) production runs smoothly. No gaps, no guesswork, no expensive downtime.

Suppliers in this space live or die by delivery precision. With real-time data, they meet those demands confidently.

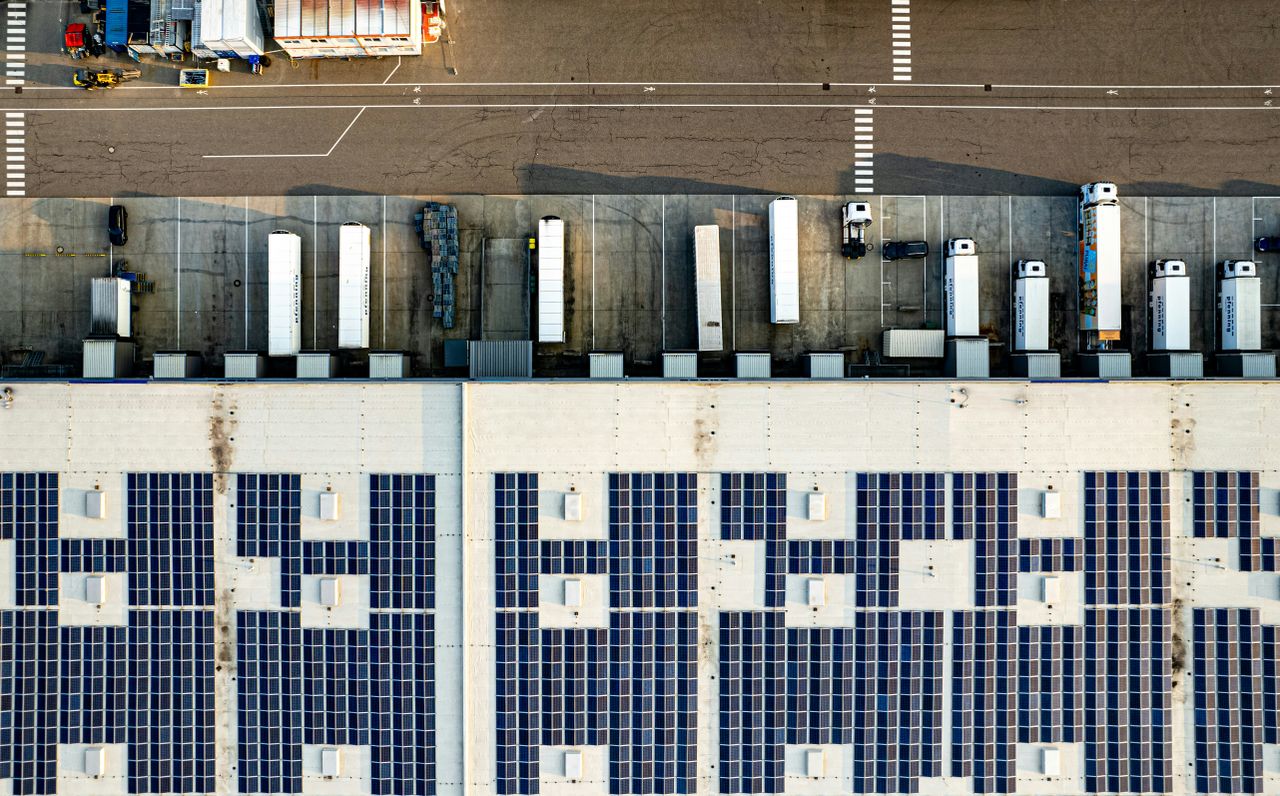

Renewable Energy Projects: Timely Execution of Large-Scale Installations

Delivering solar panels or wind turbine components isn’t like shipping t-shirts. These parts are large, fragile, and often moving on tight project timelines. Real-time tracking and integrated logistics keep delivery aligned with site schedules, so construction doesn’t stall waiting on gear.

For utility-scale projects, days matter. Every delay adds cost. Smart logistics ensures timelines hold.

E-commerce Fulfillment: Maximizing Customer Satisfaction

Speed matters in e-commerce, but accuracy is what keeps customers coming back. Integrated logistics platforms give online retailers the muscle to process orders fast and the visibility to hit promised delivery windows. That reliability shows up in reviews, referrals, and repeat purchases.

When a shopper gets what they ordered, when they expected it, with no drama — that’s brand equity.

Building Reliability and Trust: The Ultimate Benefits

This goes beyond efficiency. When your logistics operation delivers with consistency, your brand earns something algorithms can’t measure: trust. Customers don’t need to double-check tracking links. They just know their order will show up. That confidence shapes how they talk about your brand and how often they come back.

Companies that build visibility into their supply chain don’t just see better delivery stats. They see stronger retention, higher NPS, and more word-of-mouth momentum. Predictability becomes a profit lever.

You’re not just delivering products. You’re delivering on a promise — and the right systems help you keep it.

Real-Time Visibility Drives Business Success

If your logistics still rely on outdated visibility, you’re not just risking late deliveries. You’re holding back your business.

Real-time tracking and integrated logistics systems give you control, foresight, and agility. You don’t just react faster, you plan smarter, move quicker, and operate with confidence. That’s how you turn delivery into a growth strategy.

If you’re ready to raise your on-time performance to the top of your industry, talk to our team. We’ll help you unlock the tools and systems that make your operation run on time, every time.